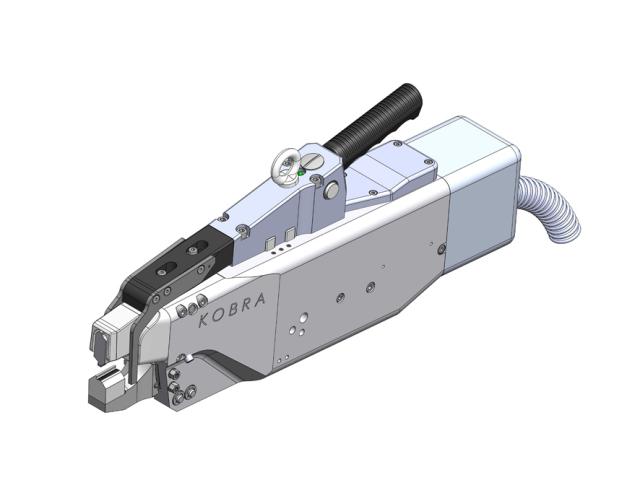

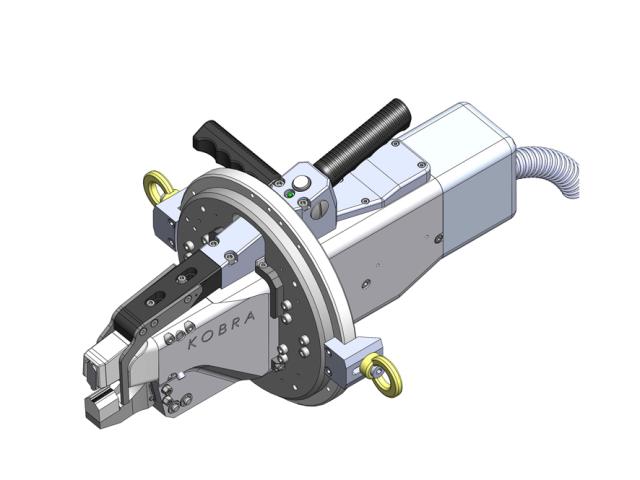

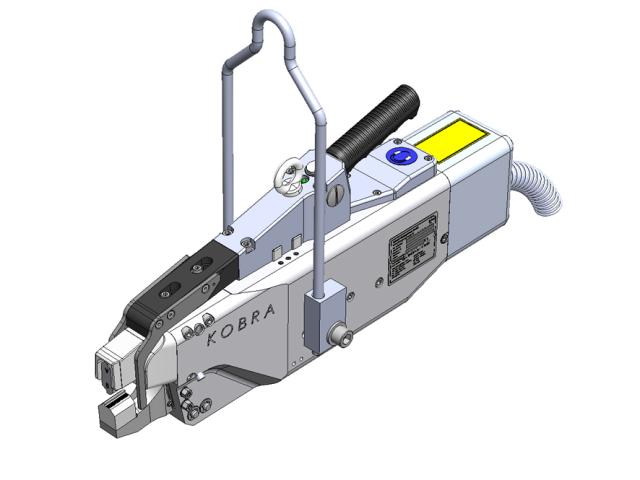

Kobra-2-Pro-Ex Ultrasonic Welder

Perfect for gas-tight welding of copper tubes in refrigeration circuits.

ultra fast. ultra robust. ultra reliable

The ultrasonic welding unit by Schunk Sonosystems, is used for gas-tight welding of copper tubes in refrigeration circuits and can be carried and operated with one hand.

The copper tube to be sealed is inserted between the tooling from the front or side and the tube is automatically detected with tube detection technology. After the tube is inserted on the welding position and the start button is pressed, the anvil fork moves upward to crimp and ultrasonically seal and cut off the tube. The tube is first welded, then automatically cut off in one operation.

The entire welding process takes less than one second and provides the most consistent and digital documented quality results.

Features

- Machine Design in accordance with CE regulations

- Ex-proof Design certified by third party – Zone 2

- Robust mechanical and electrical design of 3.500 W Power

- User friendly interface with touch screen

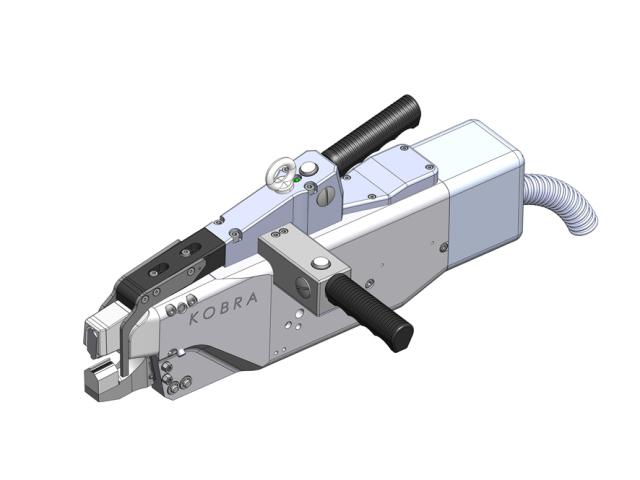

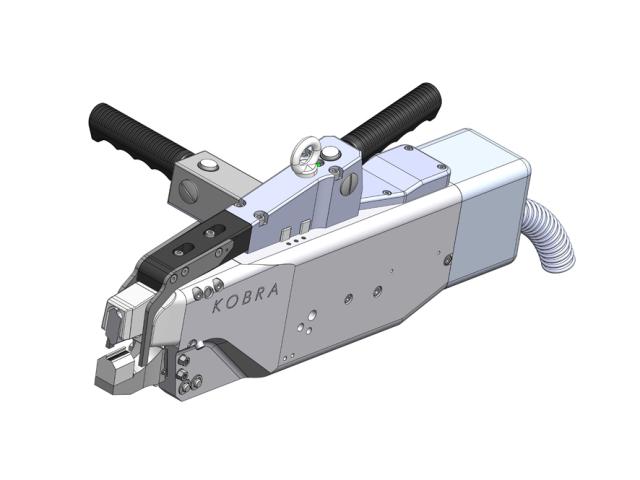

- Wide application range: outer diameter up to 10mm can be processed without changing tools

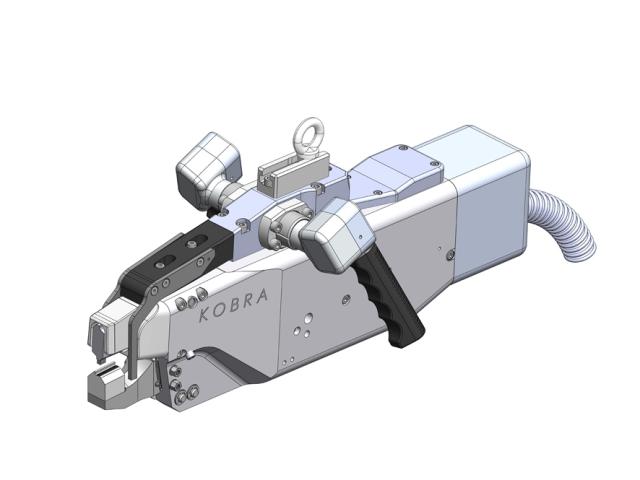

- Correct Tube Position Sensor (CTP) for excellent weld joints with “ready to weld” signal

- Easy and safe calibration procedure supported by auxiliary tools

- Dynamic process control - real time monitoring of tube final height, welding energy and time

- Process control through indicating lights on equipment handle

- Several alarm counters for process control, welding tool lifetime optimization and equipment maintenance

- Monitoring of welding position usage

- Welding series of tubes using different welding parameters (Sequence Welding)

- Barcode reader for data traceability and loading of welding recipes

- Import and Export function for welding recipes and welding results

- Full network capability and MES Data Transferring

- Easy and fast exchange of welding tools (Sonotrode and Anvil)

- Guided maintenance procedure (as per operation manual)

Connect with PLIS Factory

Document the welding process with PLIS Factory and get complete overview of the entire process. With PLIS you have full traceability and can review the proof of process of all your welding results.

Perfect companion with NO-ZONE Charging Solution

The NO-ZONE Charging Solution and the Kobra-2-Pro-Ex are the ultimate pair for safe and efficient refrigerant charging process. Safely charge with the NO-ZONE solution and weld the pipes afterwards with the Kobra-2-Pro-Ex without comprimising safety.

Kobra-2-Pro-Ex

Would you like to learn more about

Kobra-2-Pro-Ex?

Fill in the form below and we will contact you and provide you with more information