A Complete end-of-line solution for a heat pump dryer production

Electrolux looked to AGRAMKOW as their preferred solution provider for their new dryer factory in Thailand

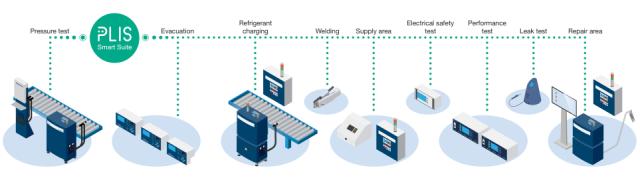

A solutions for all processes from tracer gas filling, through refrigerant charging to performance testing with PLIS Smart Suite as the center of the solutions.

Electrolux’s new factory in Rayong, Thailand, was built with world-class manufacturing standards, comprising professional refrigerator and laundry solutions manufacturing lines. This factory is one of Electrolux’s three major global manufacturing sites and has been designed for future product development to meet customer’s needs and sustainability trends.

When Electrolux decided to put up a new dryer line, they did thorough research and analysis to find a premium quality solution provider. They finally chose AGRAMKOW, as they have confidence that AGRAMKOW solutions could fulfill their requirements for high-volume production, uncompromised safety, and high-quality output.

With the long-standing partnership that Electrolux and AGRAMKOW have developed, and the proven successful experience from their sister company in Poland, Electrolux in Thailand can count on the high level of quality and support from AGRAMKOW, as they had experienced from other part of the world.

Electrolux is a leading global appliance company and through their brands, they sell more than 60 million household and professional products in more than 150 markets every year. To meet rising demand, Electrolux expanded their production in Thailand and moved to a new facility. The 18,000m2 newly built factory is designed to optimize costs and create state-of-the-art working environment in line with the highest sustainability standards.

"Based on the positive recommendation that we got from our sister company in Poland, the long harmonious working relation and good local support team, we selected AGRAMKOW as our supplier. The products are reliable and covers all the manufacturing application requirements and meets all our safety standards."

Mr. Sitipon Srisuwan

Manufacturing Engineering Manager

Working with flammable refrigerants can present significant safety risk that must be carefully managed to prevent accidents. With proper precautions, it is possible to safely use these materials to produce energy efficient and environmentally friendly products. It was important that the solution met all the safety standards established by Electrolux as they maintain a high level of safety in their factory.

The solution had to be able to perform all the tasks required in each area, the equipment should be easy to use for the operators and meet the takt time requirements for their mass production.

Furthermore, they needed a software solution to have a centralized overview of all the equipment, manage processes, analyze data, and generate reports. It was important to be able to have full traceability of the products throughout the production line so as to guarantee product quality.

A complete end-of-line solutions for all processes from tracer gas filling, through refrigerant charging to performance testing with PLIS Smart Suite as the center of the solutions.

The solution AGRAMKOW offered, met all their specific needs for performance, safety, and ease of use. It also enables Electrolux to achieve their production goals and meet the growing demand for their dryers.

The implementation of the project was smooth, and the line was operational well within the given timeframe. Electrolux was impressed with the level of support provided from the initial consultation to the final installation, especially the local support and the experience of the service team.

With PLIS Smart Suite, they can monitor all equipment operations, process data, and get detailed reports to ensure consistent product quality and production efficiency. PLIS provides them with overview of status and health of all the equipment, stores a complete history of result and can grow with them if they add more equipment at later stages.

Get a glimpse into our world and the solutions we have provided for our customers

Electrolux looked to AGRAMKOW as their preferred solution provider for their new dryer factory in Thailand

With the No-Zone charging solution in place, Vesttherm is now able to charge flammable refrigerants safely and accurately ensuring consistent product quality and higher productivity

The COVID-19 pandemic has created unprecedented conditions, challenging AGRAMKOW and our customers to collaborate in innovative ways

AGRAMKOW makes it easy for customers to act on climate threat by upgrading their production lines and transform to natural refrigerants.